Matsukaze - Wind in the Pines

The Steel

The steel traditionally used for forging Katana in Japan is tama-Hagane, a steel made from iron sand (satetsu) using a smelting process to get rid of the unwanted admixtures. Tamahagane is heterogeneous and is partly characterised by a high carbon content. It is also low in undesirable admixtures such as sulphur and phosphorus. But it is hardly first choice for a smith for a katana in the 21st century.

Matsukaze’s blade is thus forged from shirogami III (shirogami-ko) steel. Shirogami is a very pure Japanese high carbon steel with the least amount of impurities in the form of sulfur (S) and phosphorus (P). carbon (C) is at 0.8%. It is similar to AISI W108 and clearly superior to steel commonly used for practitioners blades like AISI 1095. The name white paper steel results from the white paper manufacturers used when wrapping the blade after forging. It hardens to a Rockwell hardness between 58 and 63. t

Forging Matsukaze

Shirogami-Ko has a narrow range of temperatures for hardening and requires an experienced blacksmith. All Matsukaze blades are constructed, like the majority of historic katana, in kobuse around a Shingane of mild steel. Please check out our blog if you want to learn more about the actual forging process. The blade you will order will be forged to your needs and specifications regarding its dimensions We are also offering a range of different of different hamon-types. But please note that very intricate hamon will cost extra and you would be well advised to listen to our smith if he has any concerns regarding your choices.

While we are currently concentrating on katana, we are planning to also offer wakizashi and tanto in the course of late 2023, so you will be able to build your own daisho.

Polishing

All Matsukaze blades are meticulously hand-polished on natural stones by an experienced togishi. We checked out a number of different togishi in Japan, Europe and the US and finally ended up with two that we found to deliver the best results at reasonable cost. Although the steel that is being used is obviously non-folded, our polisher managed to bring out a fine and dense hada in the jigane. Since shirogami-steel is a bit harder than tamahagane, it also takes a bit more elbow-grease to polish.

We generally tend to go for a “Iai-polish” instead of a full juyo-grade polish, but, of course, our polisher is also willing to put in extra work (at extra cost) to go the full nine yards to a full “nihonto-class” togi, if you so choose.

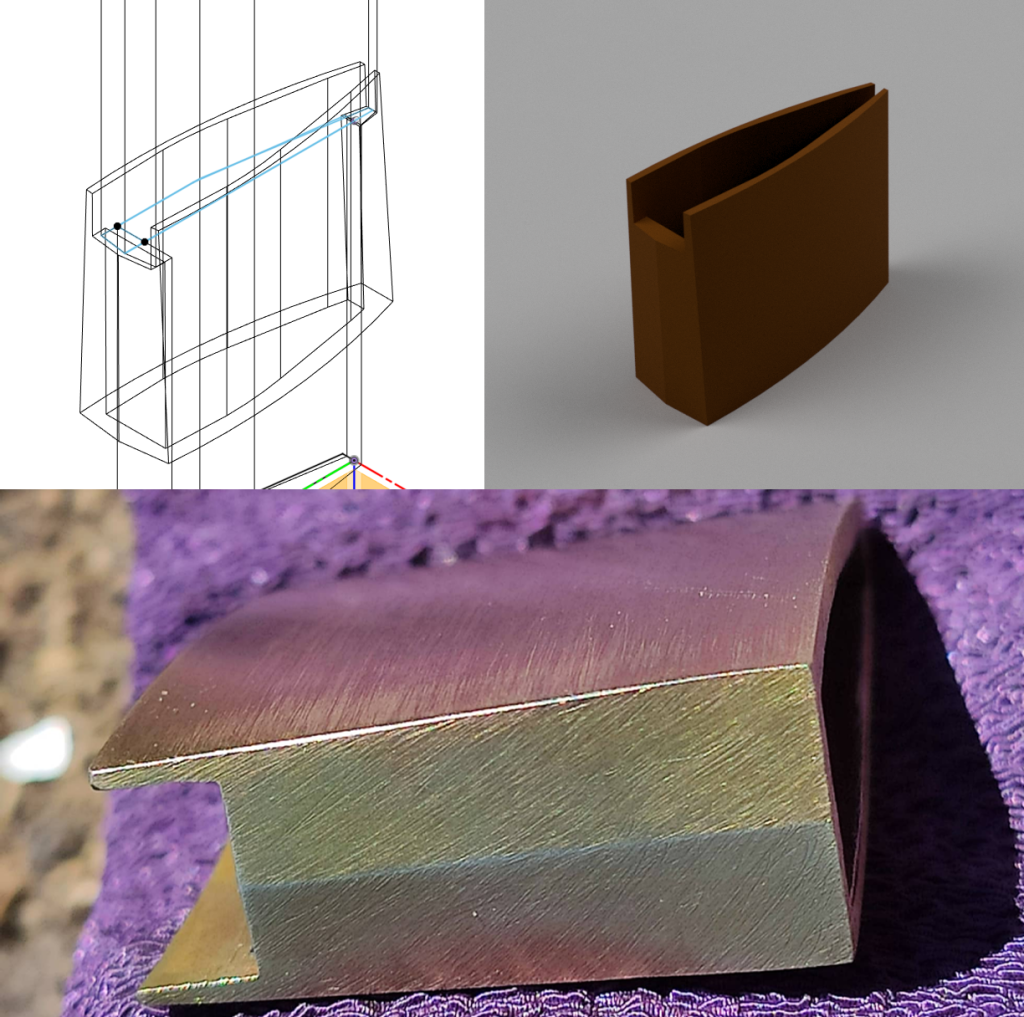

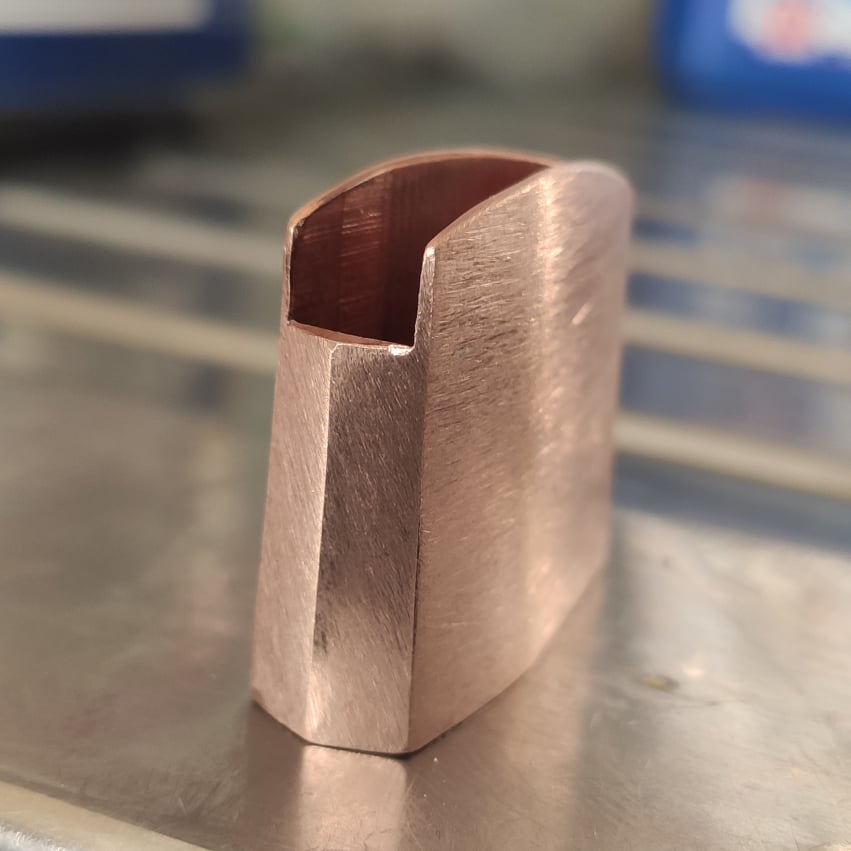

Habaki

To guarantee an optimal fit, short of having a traditionally made habaki, we took what we think is the next best approach to end up with a well-fitted habaki: we model the habaki in 3D around a “dummy” blade based on measurements taken from the individual sword and print several plastic prototypes to ensure the best possible fit. The habaki is then professionally cast in a lost wax process in either brass, copper or sterling silver.

The final finish is done by Manuel in Italy, adding file marks, sharpening the edges.After that, the habaki is patinated to either a deep golden shine for brass or in rokusho (a stunningly deep burnt orange patina).

Of course you can also get Matsukaze with a fully traditional habaki made in Japan but please note that this will add at least €300 to the cost. From a practical perspective, there is certainly no upside.

Seppa

The seppa is a component that is often not getting the attention it deserves. Structurally/dynamically, it is key to distributing the loads occuring while a Katana is being used, whether during iai or tameshigiri. Aesthetically, most people don’t really notice it unless it is an ill-fitting, run-off-the-mill brass “washer”, which everybody will point out :).

For Matsukaze, all seppa are therefore hand made to not only guarantee a good fit, but also to not break the lines of the katana.

In the base line configuration, the Seppa are made from brass and have a kiku (chrystanthemum) edge. But you can also choose them to be made in copper with a rokusho patina. Sterling silver is also possible.

Fuchi Kashira

Fuchi-Kashira is a set of fittings that adorn the handle (tsuka) of a the katana The fuchi is the collar located at the base of the handle, while the kashira is the pommel or butt cap located at the end of the handle.

The fuchi and kashira are typically made of materials such as copper, brass, silver, or gold, and are crafted using traditional Japanese metalworking techniques such as carving, engraving, and inlaying.

For Matsukaze, we are staying true to the traditions of the Japanese metalworking craft, so, no cast fuchi/kashira here. Our f/k tend to be on the sober and simple side.

Not only for cost reasons but also because Matsukaze is meant to be a practitioner’s sword and therefore we prefer a more utilitarian look instead of mounting something that probably got a lot of “ohs” and “ahs” at court in Edo times, but wasn’t really meant to ever see any “action”.

Tsuka, Same & Tsuka-Maki

What else ?

Every Matsukaze comes in a Fukuro (bag) that is as unique as the sword it contains. We have our Fukuro made from old Kimono and Obi by a small shop in Japan.

A sword like Matsukaze deserves better than being delivered to you in a cardboard box or, even worse, in one of those gaudy boxes used by many non-Japanese Katana-shops. We therefore have boxes made from Basswood by a German company with wooden pedestals fit to your sword.

Each sword is registered with a serial number and the owner’s name with the smith and comes with papers warranting its auenticity and a photobook showing how your individual Matsukaze was made.